PROCESS AND SYSTEM ENGINEERING SERVICES

AMT can provide guidance and assistance on design and specifications to meet quality goals for grass roots or modernization / revamp projects. AMT offers it's expertise in performing system engineering and verifying the designs with simulation studies. We offer the following services:

Distillation Column Design / Fractionating Column Design

Packed Distillation Column Design

Column and Internals Sizing and Optimization

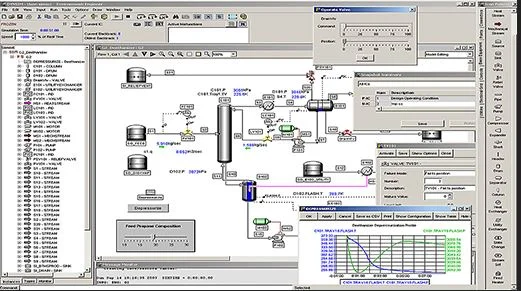

Process Simulation, Optimization and Feasibility Studies

Troubleshooting and Debottlenecking

Basic Engineering Packages

New Process Development and Design

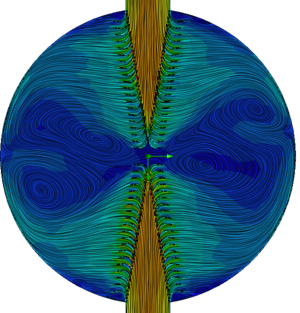

Computational Fluid Dynamic (CFD) Modeling

Ask about our Process Guarantee

DESIGN

AMT's Process and System experts have an average experience of over 30 years. Their combined experience has resulted in over 70 patents that have pushed the boundaries of the industries capabilities.

Computational fluid dynamics study

We offer CFD analysis for design optimization and validation of flow and thermal performance. For critical design requirements we recommend performing CFD analysis. This is especially important for specialized inlet designs where distribution is key to column performance.

OPTIMIZATION and balancing

AMT uses our expertise, know-how, analytical, empirical, and numeric methods to find the best solutions for your process needs. We have in house programs that will automatically find the best solutions to process and system needs for internals.

FLOW DISTRIBUTION TESTING

Ensuring our designs meet your requirements is critical, which is why we use our large scale research facilities to perform liquid flow distribution test for key equipment. We have performed research and validation testing on distributors up to 30' (9 m) diameter.

PILOT PLANT TESTING

With several sets of experimental facilities at different scales AMT can develop and pilot test new process and equipment, as well as mimetic operation for existing equipment.