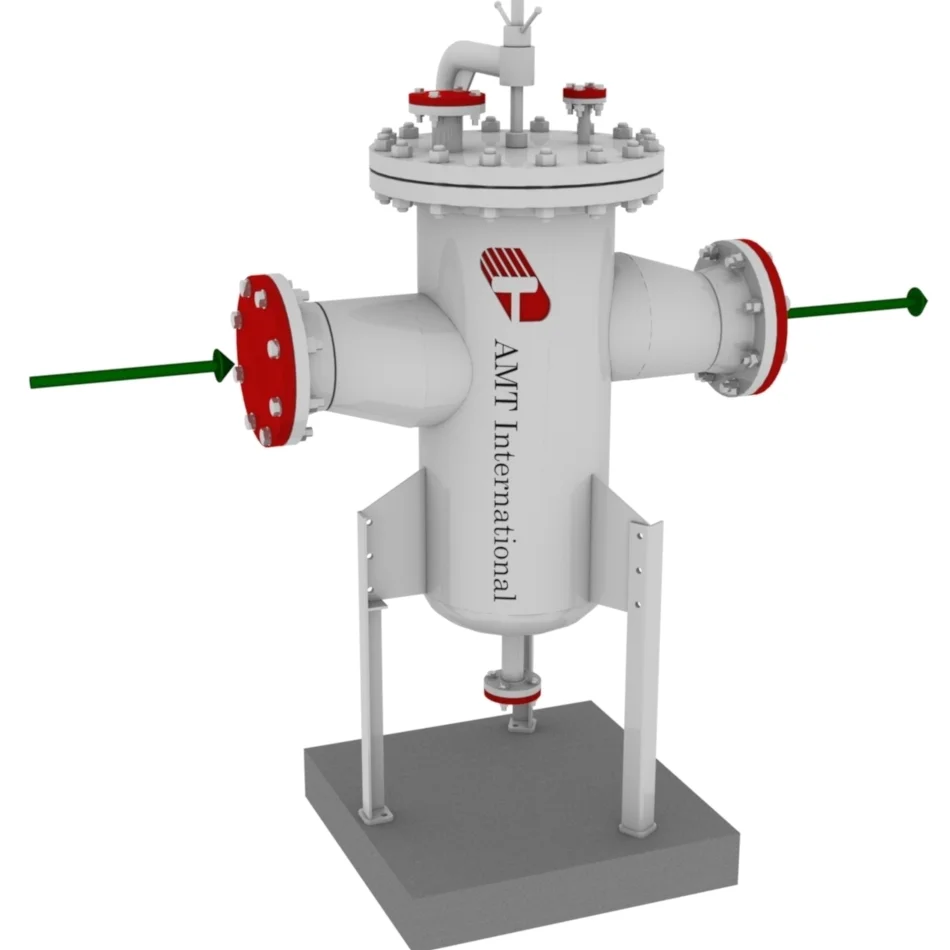

AMT ADVANCED DOUBLE STAGE (ADS) FILTERS

As a part of AMT’s process and equipment know-how in aromatics recovery, AMT’s field-proven, high efficiency Advanced Double-Stage (ADS) Filter offers a superior substitute to the conventional in-line filter to effectively remove the impurity particles, extend solvent life-span, and lower operating and maintenance costs.

When solvent is pumped through the in-line ADS Filter, most iron particles are removed in the first filtering stage via the specially designed cage; the finer polymers are then collected through the second stage basket. From the double-stage filtering, the impurities in the solvent can be effectively separated, removed and disposed.

THE AMT ADS FILTER ADVANTAGE

Compared with the typical conventional filters, the ADS Filter offers the following advantages:

1. Maintain solvent quality and extend solvent life span.

2. Allow for longer filter run-time and reduce the filter maintenance frequency.

3. Reduce maintenance costs - the ADS Filter can be simply cleaned and reused without replacing any consumable parts or cartridges.

4. Reduce Monoethanolamine (MEA) usage by over 50% (typical), thereby reduce the operating costs.

5. Reduce system equipment and piping corrosion due to the build-up of corrosive material, and extend their run-time.

6. Reduce Solvent Regenerator processing load, thereby reduce solvent loss and energy consumption. Lower solvent loss makes it environmentally safer and eco friendly since VOC emission during slurry removal from Solvent Regenerator is harmful to operators and the environment.

7. The two-stage separation of iron-oxide and polymer particles makes it easy to dispose the filtrates.

AMT ADS FILTER APPLICATIONs

The AMT Double-Stage High Efficiency ADS Filter is most advantageous in replacing existing in-line filters of any Aromatics plants for maximum solvent life-span, minimum corrosion, minimum solvent loss and maximum run-time.

The ADS Filter is also suitable for other applications which can benefit from its double-stage filtration ability. The ADS Filter is also suitable for other applications which can benefit from its double-stage filtration ability.

The High Efficiency ADS Filter has been applied in many commercial Sulfolane aromatics recovery units and proven it’s superiority over conventional filters in the past.

AMT ADS FILTER features

Durable Shell

The ADS Filter is designed and fabricated to withstand severe operating conditions, such as high pressure and high temperature. The shell’s heavy wall construction is designed to meet ASME Standards.

Stage One: Magnetic Core

The first stage of ADS Filter’s double stage operation is filtering through Magnetic Core. The sub-micron size ferrous particles, which cannot be caught by even the finest mesh screen, can be attracted and retained by the Magnetic Core.

Stage Two: Mesh Screen Basket

The second stage of ADS Filter’s double stage operation is filtering through Mesh Screen Basket. The Mesh Screen Basket features the multi-layer design of square weave mesh. It ensures both the effectiveness and durability of the mesh screen basket.

“V”- wire mesh precision screen upgrade is available upon request to improve performance and strength of your new AMT ADS filter.

Magnetic Core as an Add-On Option to Your Existing Filters

In most cases, the Magnetic Core can be added without any modifications to your existing single stage filters. You can provide your existing filter design configuration to AMT and we will work with you to improve its performance.

In-line or Off-setting Lines

Our ADS Filters can be designed to fit your current or future piping layouts with both in-line and offsetting line design schemes. This allows AMT to adapt to your specific application as required.

Customized to meet your Application

One size does not fit all. AMT sizes, designs, optimizes, and balances your ADS Filter design(s) as needed to best suit your design performance, application, and strength requirements.