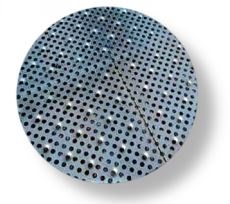

SIEVE TRAYS

FEATURES

A sieve tray is a mass transfer tray with circular perforations punched through the active areas on each tray floor. These holes typically range in diameter from 3/16” [4.7mm] to 1” [25.4mm] based on pressure drop and operating capacity.

Because no additional valve pieces are required, the sieve tray is one of the most economical trays.

AMT offers high performance trays including our ADV Pinnacle Performance Trays and ADV-MP High Capacity Trays that may be able replace existing conventional trays to help achieve significantly higher performance.

ADVANTAGEs

Low Cost

Simplest Design

Moderate Pressure Drop

Average Capacity

Average Efficiency

operation

Vapor passes through the perforated holes in the tray deck and interacts with the liquid on top of the tray deck. Sieve trays have a higher entrainment rate due to liquid bypassing trays through the holes in the tray.

Efficient operation can be achieved by having a high enough vapor velocity to balance out the liquid head on the tray, thus reducing weeping through the holes.